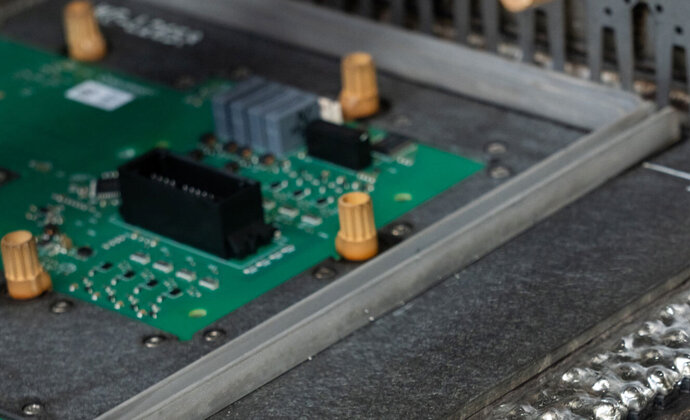

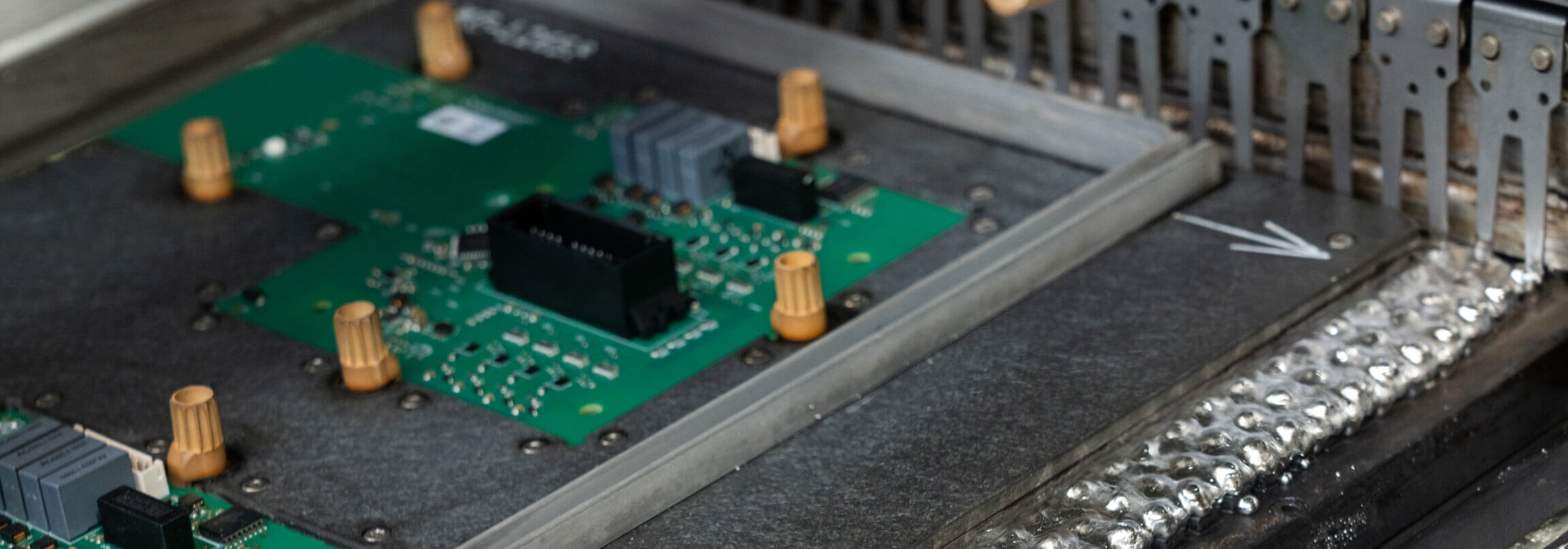

Even for the most complex assemblies

With our 4 wave soldering systems from Ersa, we are able to solder even the most complex assemblies with high heat requirements and meet our customers' high quality standards.

By using modern assembly tables with camera-guided assembly and inspection, we support our employees in their daily work and ensure the quality of the products. In addition, the application of new technologies and production tools, the automated transport of assemblies, and our highly qualified/experienced staff enable us to be very flexible, to the benefit of our customers.

All our wave soldering systems are operated under a nitrogen atmosphere, which ensures the quality of the soldering results.

Additionally, through the use of THT AOIs (Through-Hole Technology Automated Optical Inspection), we not only verify the position and polarity of the assembled components but also assess the quality of the solder joints.